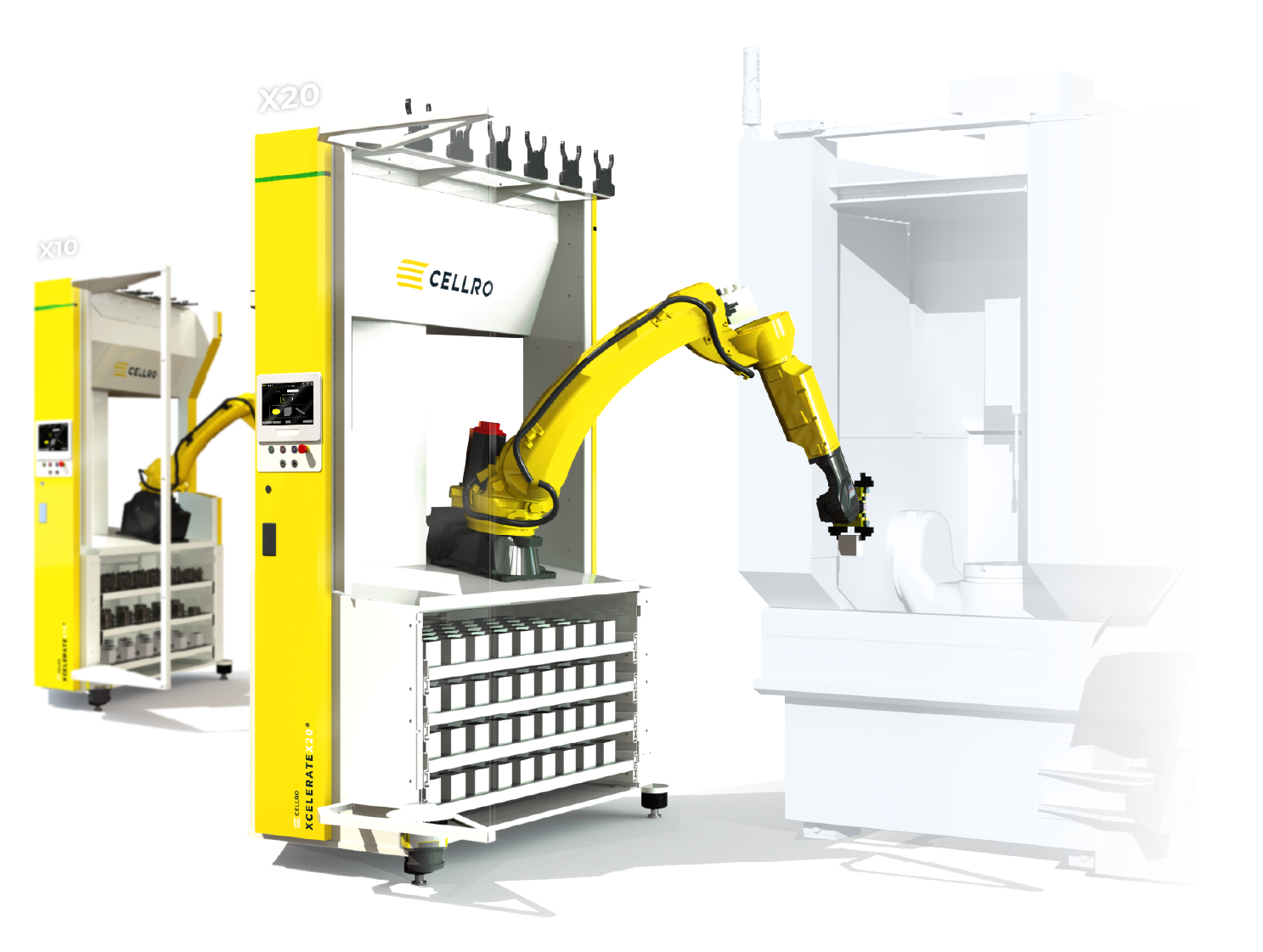

Xcelerate X10 & X20

The affordable start for any form of CNC automation

that grows along with your product mix.

that grows along with your product mix.

✔ For round parts, square parts and shafts, from small to large

✔ Suitable for aluminum, plastic, steel and cast parts

✔ Combine product and pallet handling in one automation

Suitable for any CNC machine.

New and existing.

%20(Medium).jpg?width=1200&length=1200&name=Low%20res%20-%20Cellro_xcelerate_x20_haas%20(14)%20(Medium).jpg)

-1.jpg?width=1200&length=1200&name=Low%20res%20-%20Cellro_xcelerate_x20_rc2_6s_GROB%20(13)-1.jpg)

.jpg?width=1200&length=1200&name=Low%20res%20-%20Cellro_xcelerate_x20_makino_DA300%20(2).jpg)

.jpg?width=1200&length=1200&name=Low%20res%20-%20Cellro_xcelerate_x20-35_grob_G350%20(7).jpg)

%20(Medium).jpg?width=1200&length=1200&name=Low%20res%20-%20Cellro_xcelerate_x20_mori_nt4250_1500%20(1)%20(Medium).jpg)

%20(3).jpg?width=1200&length=1200&name=Low%20res%20-%20Xcelerate_x10_dmg_milltap700%20(Medium)%20(3).jpg)

%20(Medium).jpg?width=1200&length=1200&name=Low%20res%20-%20Cellro_xcelerate_x20_haas%20(14)%20(Medium).jpg)

-1.jpg?width=1200&length=1200&name=Low%20res%20-%20Cellro_xcelerate_x20_rc2_6s_GROB%20(13)-1.jpg)

.jpg?width=1200&length=1200&name=Low%20res%20-%20Cellro_xcelerate_x20_makino_DA300%20(2).jpg)

.jpg?width=1200&length=1200&name=Low%20res%20-%20Cellro_xcelerate_x20-35_grob_G350%20(7).jpg)

%20(Medium).jpg?width=1200&length=1200&name=Low%20res%20-%20Cellro_xcelerate_x20_mori_nt4250_1500%20(1)%20(Medium).jpg)

%20(3).jpg?width=1200&length=1200&name=Low%20res%20-%20Xcelerate_x10_dmg_milltap700%20(Medium)%20(3).jpg)

6 benefits of Xcelerate X10 & X20.

Accelerate your CNC production with Xcelerate. Now and in the future.

Modular design

The modular design makes it easy to expand with new functionality when your production requires it.

Advanced by default

Use proven and standard technology, specially developed for the machining industry

User-friendly

It is so simple that operators can create new products and production jobs within 3 minutes, without robot knowledge.

Future-proof investment

Start smart with only the automation you need now. Expand later without high additional costs.

Customization possible

We are happy to adapt Xcelerate to your specific production needs for maximum production efficiency.

For every machine and process

Versatile for milling, turning, grinding and eroding. For every brand and also as a retrofit.

Start smart with Xcelerate X10 & X20.

The modular construction allows you to easily add new functionality after installation without losing your initial investment. That is a smart start.

START version

Want to produce a single product series unmanned? Start smart with the START version of Xcelerate X10 or X20.

Xcelerate X10 or X20 START is the ideal choice for the automation of a single product series in which an operator manually switches both the machine and the robot to a new product series.

SMART version

Want to produce several product series one after the other without human intervention? The SMART version of Xcelerate X10 or X20 is the right place to start.

Xcelerate X10 or X20 SMART is the ideal choice for the highly flexible production of multiple product series, where the automatic changeover of the robot cell and CNC machine enables long-term unmanned production.

Standard: The most advanced.

In addition, we can make custom-made products that fit your production exactly.

Job manager

Process different product batches one after the other without interruption.

Gripper exchange

Automatically change grippers when required by a different workpiece or product.

Vise exchange

Automatically switch from a machine clamp, chuck or collet to another workpiece or product.

Centering station

Automatically center workpieces for extra precision for OP10 and OP20.

Cleaning module

Remove cooling water, shavings or other contamination on workpieces or clamps with compressed air.

SPC

Automatically set aside products for quality measurements with Static Process Control.

Second operation

Turn products around for a second operation in the CNC machine.

AGV & Europallet

Integrate the supply and removal of workpieces and products via AGV or Euro pallet in your production.

Linking additional processes

Configure up to four additional processes before or after the machining.

Drawer lock

Place taller workpieces in the bottom drawer by locking the top drawers.

Flexible use of inlays

Place different workpieces in the same inlay. One workpiece type per inlay pocket.

2 products in cycle

Configure a second process in a machine with a dual clamping option.

Proven versatility in practice.

Let's hear from our clients

Joep Geudens

Co-owner, G.A.B. Metaal

“With two Xcelerates, we get an extra 200 spindle hours every week. During the day, we make one-off pieces and in the evening, we do series work.”

Rijk Imminkhuizen

Owner, IMTB

“If a customer calls on Friday afternoon, we fill our Xcelerate and it will be ready on Monday morning.”

Danny Dietvorst

Director, DMF Dietvorst

“Xcelerate runs 40 to 50 hours unmanned. It provides more peace and less work pressure.”